unsplash.com Here's a step-by-step guide on how to build a small, simple flat roof structure, suitable for a shed or small outbuilding. This guide is a simplified overview; always consult local building codes and regulations before starting any construction project. Safety is paramount; always wear appropriate safety gear.

unsplash.com Here's a step-by-step guide on how to build a small, simple flat roof structure, suitable for a shed or small outbuilding. This guide is a simplified overview; always consult local building codes and regulations before starting any construction project. Safety is paramount; always wear appropriate safety gear. Opening: Flat roofs, while requiring careful construction to prevent leaks, offer a simple and cost-effective solution for small structures. This guide walks you through the basic steps of constructing a small flat roof building.

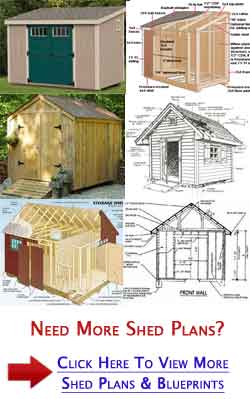

Step 1: Planning and Design: Before you begin, draw up detailed plans. Consider the size of the structure, the materials you'll use, and the slope you'll need for water runoff (even a slight slope is crucial for a flat roof). Determine your rafter spacing and the load-bearing capacity needed. Check local building codes for required permits and inspections.

Step 2: Foundation: A solid foundation is crucial. Depending on the size and purpose of your structure, you might use concrete blocks, a poured concrete slab, or even treated lumber posts set in concrete. Ensure the foundation is level.

Step 3: Wall Framing: Construct the wall frames using treated lumber. The size of the lumber will depend on the size of the structure and local building codes. Assemble the frames on the ground and then raise them into place, securing them to the foundation. Ensure the walls are square and plumb.

Step 4: Rafter Installation: Install the roof rafters. These will typically be made of lumber and should be spaced according to your plans (usually 16 or 24 inches on center). The rafters need to be securely attached to the top plates of the walls. To create a slight slope for water runoff, you can use tapered rafters or build up one side of the wall framing slightly higher than the other.

Step 5: Sheathing: Cover the rafters with sheathing, such as plywood or OSB (oriented strand board). Attach the sheathing securely to the rafters with nails or screws. Ensure the sheathing is properly spaced and overlaps to create a solid, even surface.

Step 6: Roofing Membrane: This is the most critical step for preventing leaks. Apply a roofing membrane to the sheathing. Common options include: Modified Bitumen: This is a rolled roofing material that is applied using a torch or adhesive. EPDM (Ethylene Propylene Diene Monomer): This is a synthetic rubber roofing material that is glued to the sheathing. TPO (Thermoplastic Polyolefin): This is a single-ply roofing membrane that is heat-welded at the seams. Follow the manufacturer's instructions carefully for proper installation. Overlap the seams properly and seal them thoroughly.

Step 7: Flashing: Install flashing around any penetrations in the roof, such as vents or chimneys. Flashing is also needed where the roof meets the walls. This will help prevent water from seeping into the structure.

Step 8: Finishing Touches: Add any finishing touches, such as trim, siding, and doors. Consider adding a gravel layer on top of the roofing membrane to protect it from UV damage and improve drainage.

Conclusion: Building a small flat roof structure is a manageable DIY project with careful planning and execution. Remember to prioritize safety, follow local building codes, and choose high-quality materials for a long-lasting and leak-free roof. Regular inspections and maintenance are crucial for the lifespan of your flat roof.

100+ Flats Pictures

unsplash.com

unsplash.com Flat On Behance

www.behance.net

www.behance.net Best 20+ Flat Pictures & Images

unsplash.com

unsplash.com  www.pinterest.com

www.pinterest.com  forums.autodesk.com

forums.autodesk.com  forums.autodesk.com

forums.autodesk.com  www.freeimages.com

www.freeimages.com  www.customwheeloffset.com ```html

www.customwheeloffset.com ```html  www.personalcollection.com.my

www.personalcollection.com.my  www.personalcollection.com.ph

www.personalcollection.com.ph  tuffproducts.com

tuffproducts.com  en.wikipedia.org ```html

en.wikipedia.org ```html  www.flickriver.com

www.flickriver.com  www.sciencephoto.com

www.sciencephoto.com  www.cranneystorage.com ```html

www.cranneystorage.com ```html  www.holdstorage.co.uk

www.holdstorage.co.uk  www.kostorage.com

www.kostorage.com